Under the influence of factors such as consumer upgrading and intensified industry competition, the food industry is in a critical period of transformation and value enhancement.

In response to the increasing demand of production enterprises for intelligent transformation and digital transformation of factories, Atomrobot provides “intelligent transformation and digital transformation” application solutions for enterprises, focusing on “smart scenes+intelligent products” solutions.

On June 19-21, at the 81E40 Atomrobot booth, you will gain a deeper understanding of the latest technologies and trends in the field of intelligent manufacturing, as well as expand your network resources, laying a solid foundation for future cooperation and development.

Advantages: dual follow-up/multi machine linkage high-speed sorting/intelligent material distribution precise positioning/high stability

Advantages: dual follow-up/multi machine linkage high-speed sorting/intelligent material distribution precise positioning/high stability

Process: Non neat materials with dual track layout are visually recognized and then picked up and neatly placed in the following material slots by two robots; After the material enters the trough, it is transported to the other side, and the third robot takes out the material from the trough and places it back on the conveyor line, circulating it in sequence. One feeding robot uses a storage end that can continuously absorb multiple layers of materials and release them all at once, while the other uses a single gripping end to complete a high-speed single gripping demonstration; The material retrieval robot uses multiple grippers to rotate the end, completing the extraction of multiple materials and multi angle placement at once.

Advantages: 240PPM/highest beat ± 0.02/highest accuracy 9kg/maximum load 360 ° rotation/front and back installation

Process: The equipment showcases different chocolate entry processes on the automatic production line, which can meet the requirements of orderly arrangement of different chocolates on the conveyor line, camera recognition and positioning, and automated production of SCARA robots for high-speed picking and discharging of materials.

Advantage: Production counting QR code reading, high-speed grasping, and precise positioning

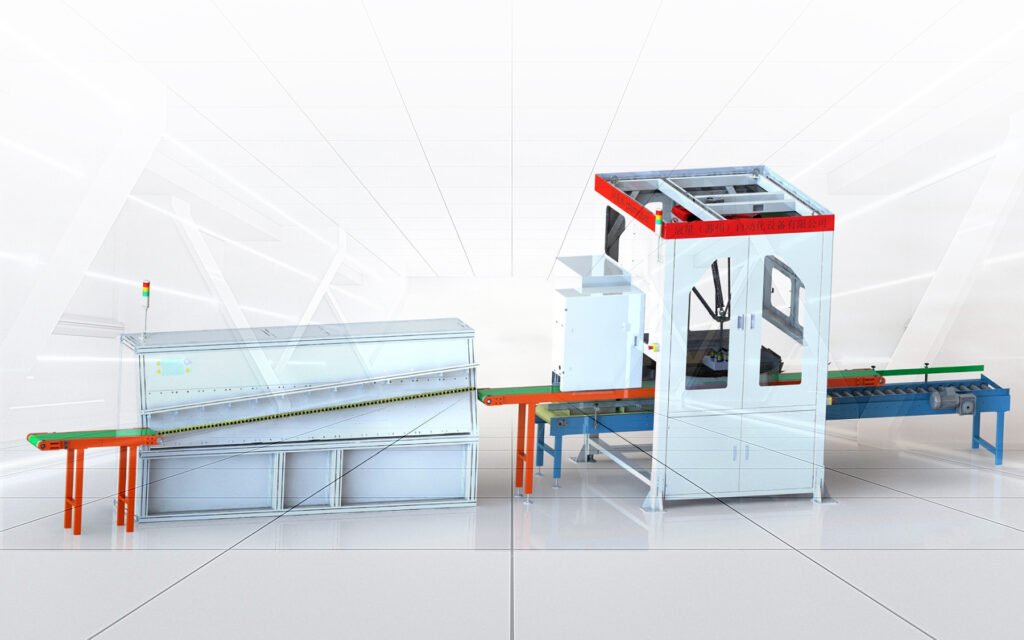

Process: The equipment displays the sorting of packaging soft bag products on the automated production line. The product can meet the requirements of separation, turning, arrangement, shaping, and counting of soft bag products, so that the soft bag products have functions such as automatic quota, automatic direction, automatic arrangement, automatic counting, and automatic removal of unqualified products (stacking, linking) during the feeding process, completing efficient boxing and boxing.

Advantages: Integrated design/flexible deployment, scene switching, wide range of applications, lightweight and flexible, flexible production, real-time monitoring, security and stability

Advantages: Integrated design/flexible deployment, scene switching, wide range of applications, lightweight and flexible, flexible production, real-time monitoring, security and stability

Process: This workstation is equipped with the Astro Boy six degree of freedom collaborative palletizing robot body, implementing graphical programming, simple and efficient, and can easily use the robot without the need for proficiency in programming languages. Half an hour to master programming methods, and one hour to complete simple programming. Integrated design, lightweight and flexible, with a small footprint, easy and efficient deployment of new tasks on workstations, widely used in industries such as food, medicine, 3C, daily chemical, and printing.

Tel/WhatsApp:0086-13913596704

Email:sales@atomrobotcn.com/sales@parallelrobot.cn